Electroforming Soft Unit – for Preparation of Glass Master / thermoplastic material (Poly Carbonate Sheet) To Nickel Master

Product Description

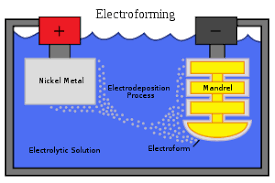

what is elector-forming Hologram masters

After hologram glass master shouted by laser beam sensitive glass by 2D/3D master shooting system(or, have dot-matrix hologram recombined into big size on some plastic film) and had one sliver layer on the surface of the glass after slivering process, we have to put the hologram glass master into soft electronic forming tank to produce Hologram Technology Master origination which image is negative to final hologram sticker. After 70-90 minutes electronic forming, we”ll get one hologram shim copy which is called nickel Hologram Technology Master origination(mother master) from the surface of glass master. Then we put the nickel Hologram Technology Master origination into another tank, hard electronic forming tank which can duplicate another piece positive operation hologram shim which is a little bit harder than soft shim for hard embossing and soft embossing. Small tank is for duplicating small master which is used to emboss hologram sticker and big tank is duplicating big master which is used to produce hologram film.

Features:

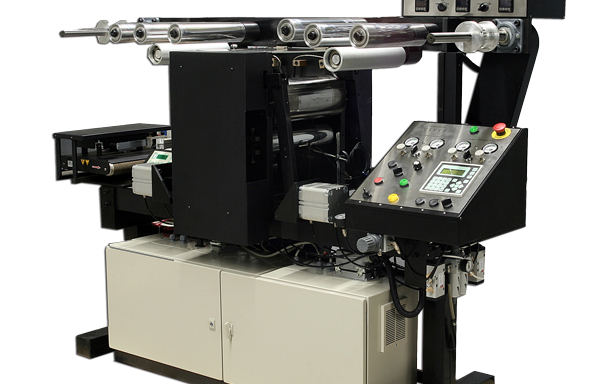

This electroforming machine is applied to duplicate the working master plate of holographic nickel plate. Mounting the original master onto the plate rack, to be replicated in the electrolytic solution, time setting and current increase & decrease according to the size of master plate.This machine consists of hard PVC made tank, high-frequency impulse, centrifugal filter, heater, positive pole, Ti-alloy positive pole, relay and digital display, which result in a quick and high fidelity of master duplicate.

Main specifications:

| Model | 800 | 1200 |

| Negative pole area | 800-330mm | 1200-800mm |

| Size of electric controller | 45 x 45 x 90cm | 45 x 45 x 90cm |

| Tank temperature | 38-43℃ | 38-43℃ |

| Max. current | 150A | 200A |

| Max. voltage | 15V | 15V |

| Power supply | 380V, 220V | 380V, 220V |

| Rated power | 3kw | 4kw |

| Machine dimension | 1.3 x 0.7 x 0.5M | 1.7 x 0.8 x 1.2M |

| Machine weight | 500kg | 800kg |

Detailed Specifications of Equipment:

This equipment has been specially designed for the replication of Holographic Glass Master to Nickel Shim shims by means of an Electro-forming Process. The process consists of Electro-deposition of Metal (nickel) on a model (Glass Master) capable of conducting electric current. When the deposition is complete it is possible to separate from the Master a new Nickel Copy which is an exact negative of the Master.

The design parameters of this equipment is to provide a constant supply of the necessary quantity of quality Shims for the Embossing Machine , thus making the end-user of our equipment to be fully independent of all production activities , excepting preparation of the Master.

Unlike other suppliers of such equipment who manufacture and supply only the Electroforming Tank and expect the buyer to procure the necessary Chemicals and consumables independently, Holographic Origination & Machineries Ltd. offers a complete package including all chemicals and consumables to enable the buyer to start commercial production of Quality Holographic Products from day- One .

- Shim Size: 250mm X 250mm / any size will be available

- Process Control Current & Volt: Motorized Variable

- Temperature Control: Programmable

- Cycle Duration Control (Timer): Programmable

- Voltage: 230 Volt A.C. – 50 Hz

- Power Consumption: 5 Kw max.

- Capacity of Machine: 10 Pcs. Master (Max) Per Day

- Pump & Filter: Included

- Weight: 500 Kg (Approx)

- Approx Dimensions: 1 m X 0.6 m X 0.6 m